Every LED screen can stand the test

Why Quality Control Matters In LED display

In LED display manufacturing, stability and consistency determine the upper limit of the display effect and whether the customer project can be delivered smoothly. As a reliable LED display manufacturer, we know that every process must be finely controlled.

Therefore, from lamp bead screening, circuit board welding, to module aging and whole screen calibration, we implement strict quality control processes (LED screen factory strict quality control) to ensure that every screen has highly consistent brightness, color and reliability.

It is not only responsible for the product, but also a guarantee for the customer’s brand reputation and long-term cooperation.

Quality Control Workflow

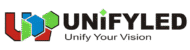

Lamp bead screening and testing

We only select LED lamp beads with high stability and consistent brightness, and conduct batch aging tests and color consistency checks to ensure that the picture is uniform and has no color difference.

Circuit board and driver IC testing

Use high-standard PCB boards and brand driver ICs, such as MBI, ICN, etc., to ensure high refresh rate, high grayscale performance, and smoother and more delicate pictures.

Module aging test

Each LED module must undergo at least 24 hours of high-temperature aging, and strictly check for potential problems such as bad lamps, dead spots, color deviation, and brightness attenuation.

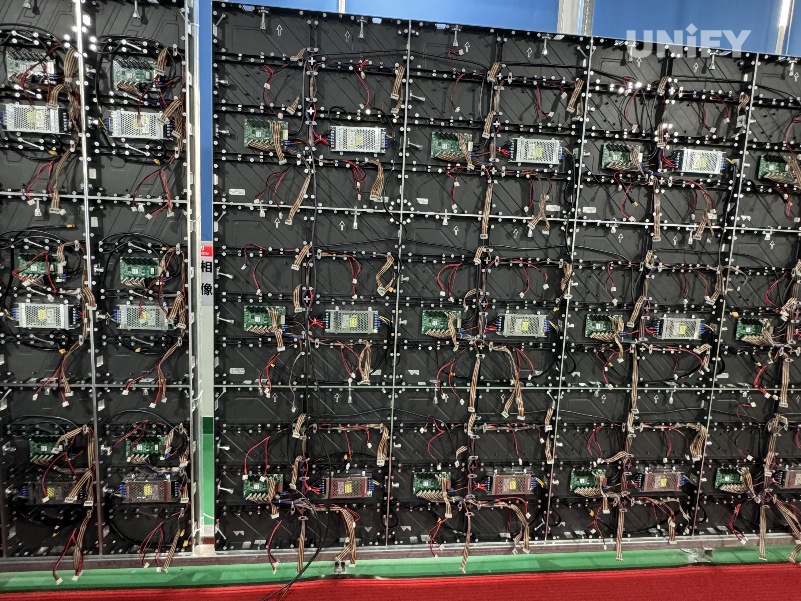

Whole screen assembly and testing

After the screen is assembled, a comprehensive test is carried out, including brightness uniformity, color consistency, dead spot detection, flatness inspection, etc., to ensure the overall display quality.

Protection performance inspection (outdoor screen)

Outdoor screens must pass professional protection tests, including waterproof level, sealing, anti-corrosion coating, heat dissipation structure, etc., to adapt to various outdoor environments.

Full screen power-on test and function calibration

Before shipment, the full screen is powered on and continuously operated to confirm that the control system responds normally, the screen is synchronized, the playback is stable, and the necessary brightness and color calibration is completed.

How to avoid common quality problems? (Preventing Common LED Screen Failures)

During the use of LED display screens, common problems such as uneven color blocks, dead lights, and loose modules will seriously affect the viewing experience and brand image. As a reliable LED display manufacturer, we start from the design source and manufacturing process to effectively prevent these problems:

● Uneven color blocks?

Full-process chromaticity correction + high-consistency lamp beads

We use an automated chromaticity correction system with strictly screened LED lamp beads to ensure the color consistency of the entire screen, avoid color difference problems, and improve the visual performance of the LED screen.

● Dead lights on the screen?

Power-on aging test for each lamp bead

All lamp beads have undergone 100% power-on testing and module aging inspection to reduce the dead light rate from the source and ensure stable output under the strict quality control standards of the LED screen factory.

● Module detachment?

Precise module structure design + strong magnetic or quick lock assembly system

Through mechanical structure optimization and reliable installation solutions (such as strong magnetic adsorption and quick lock system), each LED module is ensured to be firmly spliced, suitable for various scenarios such as rental LED screen and fixed installation LED wall.

Support for Client Inspection

Support video inspection or third-party quality inspection before delivery

Can provide complete inspection report, parameter screenshots, and real photos

Customers can specify the sampling ratio to ensure that each batch is qualified

Why Choose UnifyLED ?

As a professional LED screen factory – Unify, we insist on ensuring quality from the source, and are committed to providing global customers with cost-effective, stable and reliable LED display solutions:

Own factory production, full process control

Support customized quality inspection

Served 1000 customers in more than 58 countries

Contact Us

Apply to be a distributor