LED Display Factory in China

15‑20 working days for regular production, 48h aging test, fast delivery worldwide

Professional production factory

Unify LED is a Chinese LED display manufacturer with a modern LED screen factory of over 5,000 square meters and multiple automated production lines. Since its establishment in 2012, we have established a complete in-house production system to ensure the stability and quality of each screen.

The factory has more than 50 skilled employees and engineers, strictly follows the ISO9001 quality management system, and has passed multiple international certifications such as CE, RoHS, FCC, etc.

Currently, Unify LED’s LED display products have been exported to 58 countries and regions, including Africa, the United States and Southeast Asia, with local offices to provide fast pre-sales and after-sales services. With high brightness and strong stability, our customer satisfaction rate has reached 98%, gaining a good reputation and continuous cooperation.

How are LED displays manufactured?

Unify LED has a complete automated production system. From module production to full screen shipment, the entire process is centrally controlled by the ERP system to ensure that each LED display has traceable quality and on-time delivery capabilities. The following are our main production steps:

Lamp bead area:

The LED chips are reflowed on the SMT machine and then baked to ensure normal use and avoid dead lights.

Kit area:

The machine installs the module kit and fixes it with screws, which can better protect the LED lamp beads from being squeezed and collided and improve the luminous quality.

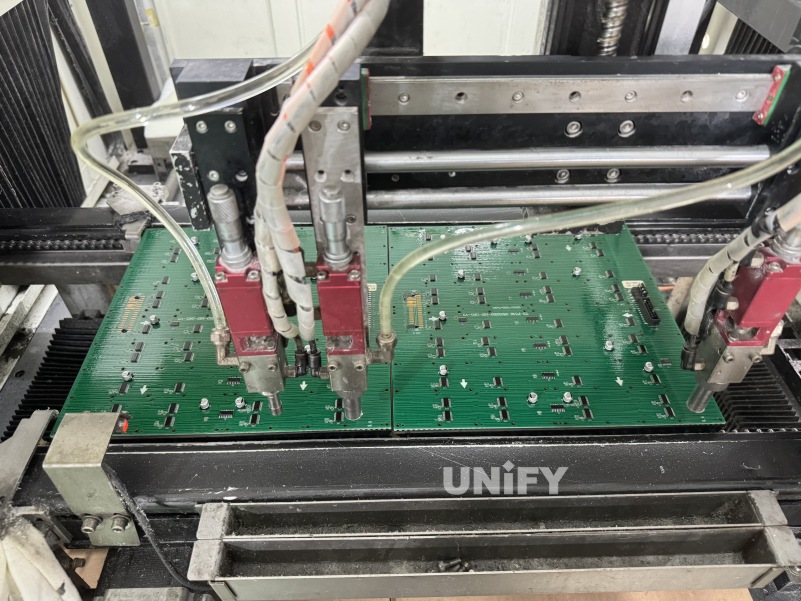

Electronic components area:

The PCB board needs to be brushed with solder paste first, and then the IC, resistor, capacitor, power socket, signal socket are pasted, and reinforced in reflow soldering

Printing area:

Applying conformal coating can form a solidified protective film on the back of the module to enhance protection. Outdoor modules are also painted with waterproof glue paint.

Assembly aging area:

After the module is aged separately for 24 hours, it is assembled with the box and powered on for no less than 48 hours.

Packing and shipping area:

multiple packaging processes such as bubble film, aviation box, and wooden box are used to ensure safe and damage-free global transportation.

Check more LED display production details

Product Range – What We Manufacture

| Category | Pixel Pitch | Application |

|---|---|---|

| Indoor Fixed LED Display | P1.25–P4 | Conference, Control Rooms |

| Outdoor LED Display | P2.5–P10 | Billboards, Stadiums |

| Rental LED Screen | P2.6, P2.9,P3.91, P4.81 | Events, Concerts |

| Transparent LED Display | 3.91–7.81 | Glass walls, Retail stores |

| Flexible LED Modules | P1.86–P4 | Cylinders, Curved surfaces |

Factory Environment Overview

Raw material partner brand

OEM & ODM LED Manufacturing Services

Personalized cabinet design, customized module size

Multi-language operating system / software customization

Private model / new display structure R&D support

2025 New LED Screen Price Check

Quick and easy: Enter your specifications and get a quote in one business day